A galvanized surface is a metal surface that has a zinc layer to prevent corrosion. We refer to the process of applying this zinc layer as "galvanizing". In addition, this application is done on steel or iron surfaces. It has been more than 180 years since the first industrial use of hot-dip galvanizing in France in 1836. The demand for hot-dip galvanizing has increased with the growing demand for protective products for high-voltage power transmission, transportation, and communications. PIPEFUN presents in this article what is known about galvanizing and hot-dip galvanizing.

Hot-dip galvanizing - where the item is dipped into molten zinc

Continuous galvanizing - a form of hot dip galvanizing, but with a thinner zinc layer

Thermal spray - semi-molten zinc is sprayed onto the article

Electroplating - using the article and zinc metal as electrodes in an electrochemical cell

Mechanical plating - a chemical plating method that uses mechanical energy and heat to deposit a coating

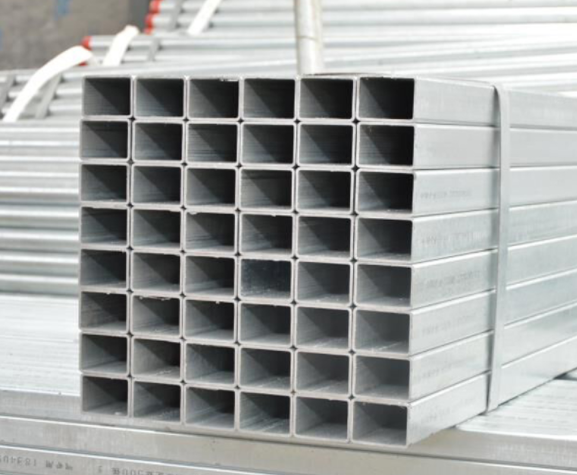

Hot Dip Galvanized Round Steel Pipe

Hot-dip galvanizing is the process of coating a metal with a zinc layer to protect that metal from corrosion. We can denote this as HDG. This process consists of three main steps: surface treatment, galvanizing, and inspection.

In the surface preparation step, we must use wires to hang or place the steel on a suitable rack. Thereafter, the steel undergoes three cleaning steps: degreasing, pickling, and flux. The degreasing step removes the dirt from the steel surface. The pickling step removes oxide and iron oxide. In the later stages of the flux, it removes any other oxides present on the steel surface and forms a protective layer that can prevent any further oxide formation.

During the galvanizing process, we need to immerse the steel in a molten zinc bath with a zinc content of at least 98%. Here, the iron in the steel surface tends to form a series of zinc-iron intermetallic compound layers and a pure zinc outer layer. In the inspection step, we need to check the coating. In addition, we need to determine the quality of the zinc layer on the surface.

Galvanized steel pipe is a carbon steel pipe coated with a protective layer of zinc. The zinc layer acts as a sacrificial layer and it rusts before the carbon steel beneath it. Galvanized steel pipe includes both hot-dip galvanized steel pipe and cold-dip galvanized steel pipe. The zinc coating will enhance the corrosion resistance of the steel pipe.

Why is zinc used? Because zinc element is more active than steel element. On the one hand, zinc oxide on the surface of galvanized steel pipe is dense and can prevent oxidation (corrosion). On the other hand, when galvanic corrosion occurs, the first metal to be corroded is zinc and not steel. The zinc layer serves to stop the corrosion rate and prolong the life of the steel pipe.

In the process of hot-dip galvanizing, a zinc-steel alloy layer is formed first, with a pure zinc layer on top. When air corrodes the zinc layer, a protective film of ZnO, Zn(OH)2 and alkaline zinc carbonate is formed. It has the effect of anti air corrosion. When this film is destroyed, a new one will be formed. When the zinc layer is severely damaged, zinc initiates electrochemical protection. As the first element of zinc dissolves. Obviously, hot-dip galvanized steel pipe has better anti-corrosion properties than cold-dip galvanized pipe.

Generally speaking, 13 years in heavy industrial areas, 50 years in marine environments, 104 years in suburban areas and 30 years in cities. In fact, galvanizing already acts as a rust prevention and no other rust prevention treatment is needed. The hot-dip galvanizing process is particularly suitable for a variety of strong acids, alkaline fogs and other highly corrosive environments. This type of fastener is used a lot outside of steel tower contributions.

Hot-dip galvanizing is a type of galvanizing. The main difference between galvanizing and hot-dip galvanizing is that galvanized materials have a smooth and sharp finish, while hot-dip galvanized structures have a rough finish. In addition, the galvanizing process involves the formation of a layer of zinc to protect the metal from corrosion, while hot dip galvanizing involves the formation of a pure zinc layer on the surface of the metal through surface preparation, galvanizing and inspection.

Please contact PIPEFUN today to buy the steel pipes you need, we also have flanges and valves for sale.

Copyright © Hebei Pipefun Pipe and Fitting Facility Co., Ltd. All Rights Reserved | Sitemap