A flange is an external or internal edge, or a rim (lip), for power, such as an iron plate flange, such as an I-beam or a T-beam; or for attachment to another component, such as a flange at the end of a screw, a steam lever, etc., or a camera lens mount; or a railcar flange or tram wheel flange.

Stainless steel flanges are available in a wide range of applications and types. If you want to know more about steel flanges, or just want to learn about some common uses, then you've come to the right place. Here are three uses for steel flanges.

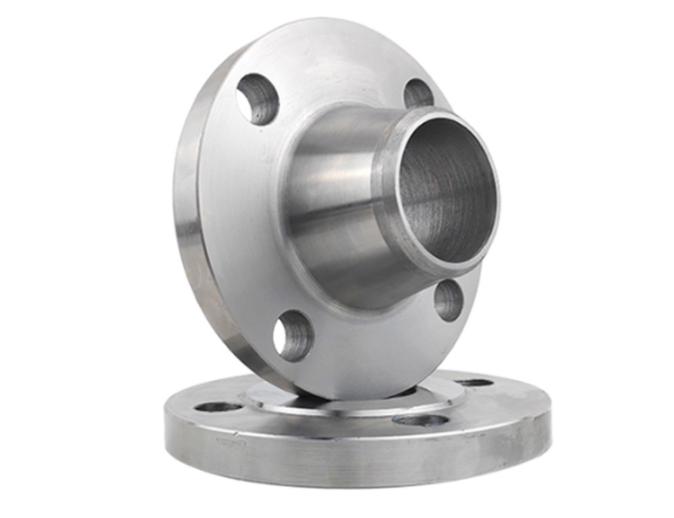

Butt-weld flanges are a stainless steel flange fitting option used to help reduce the pressure that collects at the bottom of a pipe. These are used for pipes that operate at high and low temperatures and for pipes that must be able to withstand pressure. These flanges have been used at pressures up to 5,000 psi.

This stainless steel flange fitting option is most commonly used for small diameter pipelines. This is not the type you want to use with very large lines or lines with very high pressures. This type of fitting is used to help minimize the pressure at the weld. This is not for high pressure pipelines, very large pipelines or any flange that will be under a lot of pressure.

Blind flanges are completely flat and have no holes. They are used to close the ends of pipes and valves and can also be used for pressure vessel openings. This is the type of flange that will be used to help cut off the flow to the pipe. Steel pipe flange fittings are available in a variety of sizes and pressure ratings.

SO Forged Flange slip-on steel flange

Carbon steel or medium carbon steel is an element of metal. It is a mixture of iron and carbon components. Many of the components are too small to affect their properties in quantitative terms. In pure carbon steel, the only other elements allowed are: manganese, silicon and copper. These carbon steel flanges have more carbon content for strength and toughness, but are less ductile and more difficult to weld. Higher carbon content reduces the melting point of the flange and its total temperature tolerance.

In general, forged flanges have a lower carbon free content than fused flanges. They do not oxidize quickly. They are flat and quite light in structure, and fused flanges have excellent mechanical properties. Improper forging methods often result in wide or irregular grains; hardening cracks and forging are higher than casting flanges.

According to the manufacturing cycle, forging flanges in carbon steel flanges have certain operating principles. The production method and use of carbon steel flanges provide certain operating theories. The basic idea is to use the insulation efficiency of carbon steel flange isolation gasket. Insulation using high-load carbon steel flanges, carbon steel flanges on both sides of the plant electrical insulation flange. Heavier than concrete Mary iron and galvanized pipe than steel is widely used (tanked). Stainless steel flanges factory production of mild steel In India, casting carbon steel flanges refining, forging and grinding, rivets, screws, support production, such as mild steel flanges.

The most important thing to remember is to take the time to find the right flange for the job. They may look similar, but they all have different functions and different uses. Please contact PIPEFUN to learn more about the flanges and get the quotes. We welcome your inquiry.

Copyright © Hebei Pipefun Pipe and Fitting Facility Co., Ltd. All Rights Reserved | Sitemap