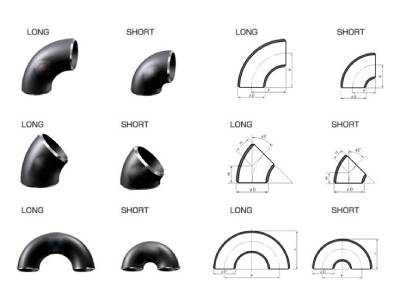

Steel pipe elbow (sometimes also called steel bends) is a key part in a pressure piping system used to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe and thus the fluid direction turn to a certain direction of 45 degree or 90 degree. This change in fluid flow direction adds pressure losses to the system due to impact, friction and re-acceleration. And there are different types of elbows, according to fluid flow direction of the pipes, elbows can be divided into different degrees, such as 45 degree, 90 degree, 180 degree. And according to the manufacturing process there are butt weld elbow, forged elbow, malleable elbows, also for various material, such as carbon steel elbows, stainless elbows and alloyed elbows, as well as the the different standards, such as ANSI B16.9( ASME B16.9), DIN 2605 , and also ISO and JIS standard elbow.

Today lets get down to know more about butt weld elbows, which are widely used in oil, gas and steam and chemical fields, ANSI B16.9 STEEL ELBOW.

Butt Welded Elbow

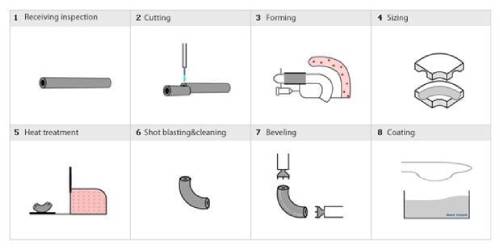

1.Butt weld elbow making process

Butt weld elbow is a steel elbow formed by hot pressing or forging. Its connection form is to directly weld the elbow and steel pipe. Butt welded elbows have beveled ends to allow for ease of welding. This bevel allows for full penetration weld in most of the cases. Butt welded elbows are mainly used for elbow with higher pressure and temperature.

2.The material of butt weld elbows:

Carbon Steel Elbow : ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Stainless Steel Elbow : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Low Temperature Carbon Steel Elbow : ASTM A420 WPL3, A420 WPL6

Alloy Steel Elbow : ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91.

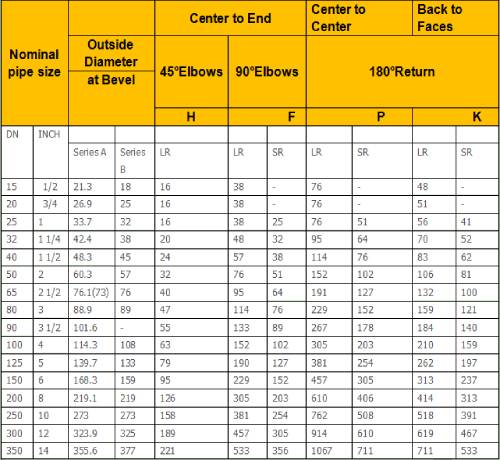

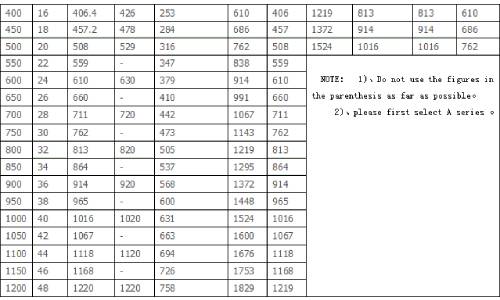

3.The dimensions of steel elbows

Copyright © Hebei Pipefun Pipe and Fitting Facility Co., Ltd. All Rights Reserved | Sitemap