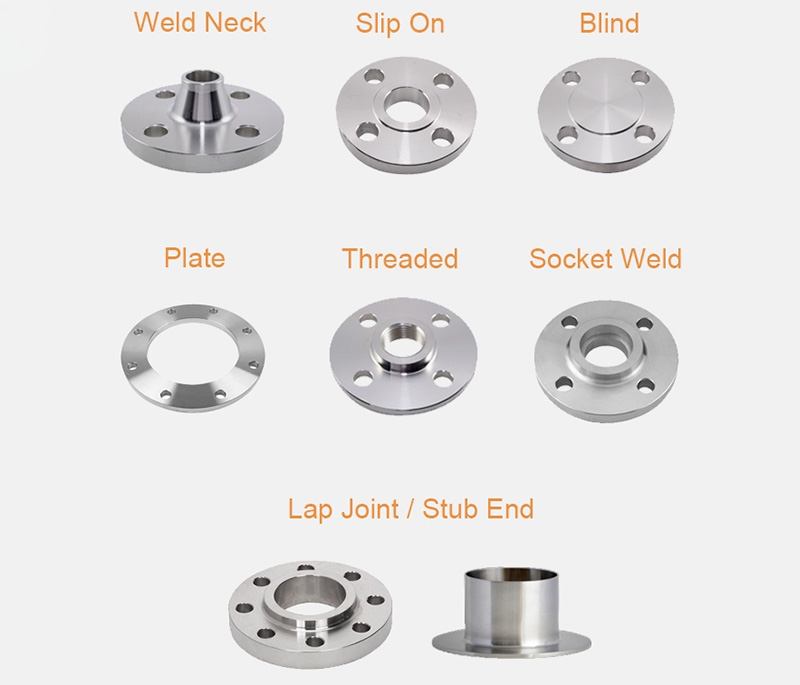

The type of flange used for piping applications depends primarily on the required strength of the flange joint. Flanges are used as an alternative to welded connections to facilitate maintenance operations. Now let's take a deeper look and show the main types of flanges.

Weld neck flanges have a long, tapered hub that can be welded to the pipe. This flange type is typically used for high pressure and high/low temperature applications that require unrestricted flow of fluids conveyed by the piping system.

The absence of pressure drop prevents negative effects such as turbulence and erosion/corrosion of the metal near the flange joint. The tapered hub allows for smooth distribution of mechanical stresses between the pipe and the weld neck flange and helps perform radiographic inspections to detect possible leaks and weld defects.

Long butt weld flanges ("LWN") are similar to butt weld flanges with the difference that the neck (tapered hub) extends and acts as a bore extension.

Long butt weld flanges are typically used for vessels, columns or drums. These flange types are also available in Heavy Duty Barrel (HB) and Equal Barrel (E) types.

Overlap flanges have a flat surface and are always used in conjunction with a short end. A lap flange is similar in shape to a slip-on flange except that the radius of the intersection of the flange face and the hole accommodates the flange portion of the short end.

The lap flange slides over the pipe and is secured to the back of the short end, and the two are held together by the pressure of the bolts. Using a lap flange in conjunction with a short pipe end is a cost effective solution for stainless steel or nickel alloy piping.

Slip-on flanges are attached to a pipe or fitting by two fillet welds, one inside the flange cavity and one outside the flange cavity.

The bore diameter of the slip-on flange is larger than the outside diameter of the connected pipe, as the pipe must slide inside the flange through the fillet weld to be connected.

Slip-on flanges are also defined as "hub flanges" and they are easily identified due to their slender and compact shape.

Threaded flanges are attached to the pipe by screwing the pipe onto the flange without seam welds. Threaded flanges are available in sizes up to 4 inches and in a variety of pressure ratings, however, they are primarily used for small pipe sizes in low pressure and low temperature applications such as water and air utility services.

Threaded flanges are also mandatory for explosive areas, as performing welded connections in such environments can be dangerous.

Contrary to all flange types seen above, blind flanges do not have a central hole and are used to close or seal pipes, valves/pressure vessels and to stop fluid flow.

Due to system pressures and the required bolting forces, blind flanges must be subjected to significant mechanical stress.

Blind flanges allow easy access to the pipeline because they can be easily loosened, allowing the operator to perform activities within the pipeline terminals.

Socket weld flanges use a single fillet weld executed on the outside of the flange to connect to the pipe, unlike sliding flange types that require two welds.

Socket weld flanges are used for small, high-pressure pipelines that do not carry highly corrosive fluids. This is because these flange types are subject to corrosion in the gap area between the end of the pipe and the shoulder of the socket.

In addition to the functional design of the flange, flange size is the factor most likely to influence flange selection when designing, maintaining or upgrading a piping system. However, you must consider how the flange interfaces with the pipe and the gasket in use to ensure proper sizing. Common considerations include:

Pipe Size: Name of the pipe size corresponding to the flange.

Nominal Bore Diameter: Measurement of the inside diameter of the flange connector.

Outside diameter: the distance between two opposing edges of the flange face.

Bolt circle diameter: the distance between relative bolt holes when measured from center to center.

Thickness: a measure of the thickness of the outer joint rim.

These are the common classifications, but there are different ways to classify them, too. PIPEFUN is a specialized enterprise professional in producing steel pipes and pipe fittings. Choosing us to be your business partner can bring you great advantages in business! We will talk about international standard of the materials later, and if you want to buy flanges here, please contact our experts and we are happy to serve you.

Copyright © Hebei Pipefun Pipe and Fitting Facility Co., Ltd. All Rights Reserved | Sitemap